Services

Whatever your challenge, we can help you. Contact us to discuss your issue.

Whatever your challenge, we can help you. Contact us to discuss your issue.

Whatever your challenge, we can help you. Contact us to discuss your issue.

In-house courses

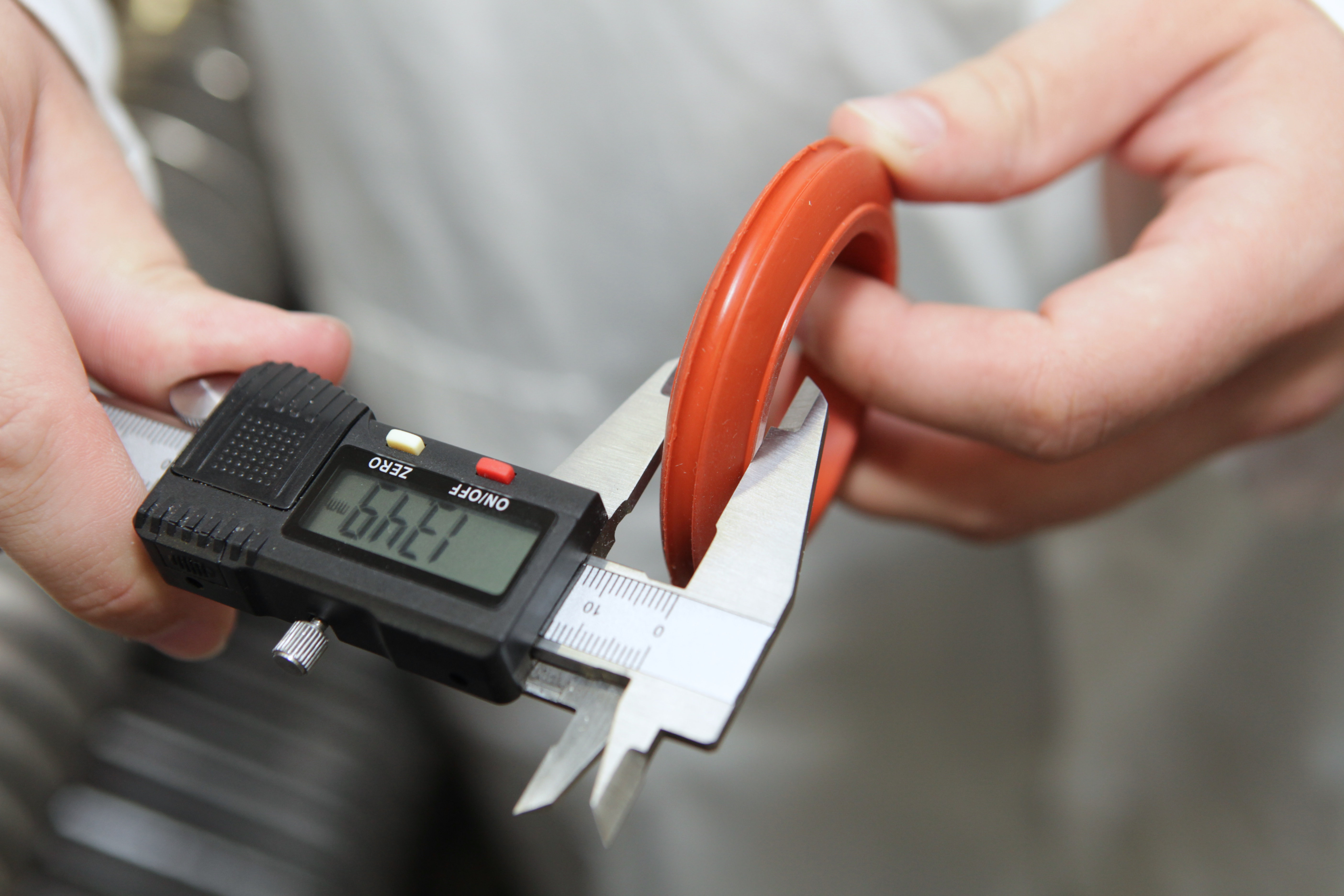

Based on the laws and regulations, which indicate what must be done in each case, supplemented with the knowledge developed in standards and white books, we provide you with the basis for designing, purchasing, and using hygienic equipment. These are the requirements and general principles for e.g. surface treatment, joining of parts, sealing of moving parts, temperature control steps, cleaning, etc. In addition, we add from our own extensive experience in design and troubleshooting what in practice are good and less good solutions, what pitfalls have been identified, and how a production line can be kept in good operation. We do this in various courses: focused on (mostly) closed production (HO - extended or HO - principles), on dry processes (water-free), on open processes (Transport systems), on cleaning (CIP), on the building (Zoning - building), and also for technicians working on the equipment (Hyg. maintenance).

You can read the content of the open version of these courses via the links, and it can be customized to your requirements and needs for in-house training. We can visit before the course for recordings of the line, so that explanation of design principles and cases can be based on your own equipment.

In-house courses

Based on the laws and regulations, which indicate what must be done in each case, supplemented with the knowledge developed in standards and white books, we provide you with the basis for designing, purchasing, and using hygienic equipment. These are the requirements and general principles for e.g. surface treatment, joining of parts, sealing of moving parts, temperature control steps, cleaning, etc. In addition, we add from our own extensive experience in design and troubleshooting what in practice are good and less good solutions, what pitfalls have been identified, and how a production line can be kept in good operation. We do this in various courses: focused on (mostly) closed production (HO - extended or HO - principles), on dry processes (water-free), on open processes (Transport systems), on cleaning (CIP), on the building (Zoning - building), and also for technicians working on the equipment (Hyg. maintenance).

You can read the content of the open version of these courses via the links, and it can be customized to your requirements and needs for in-house training. We can visit before the course for recordings of the line, so that explanation of design principles and cases can be based on your own equipment.